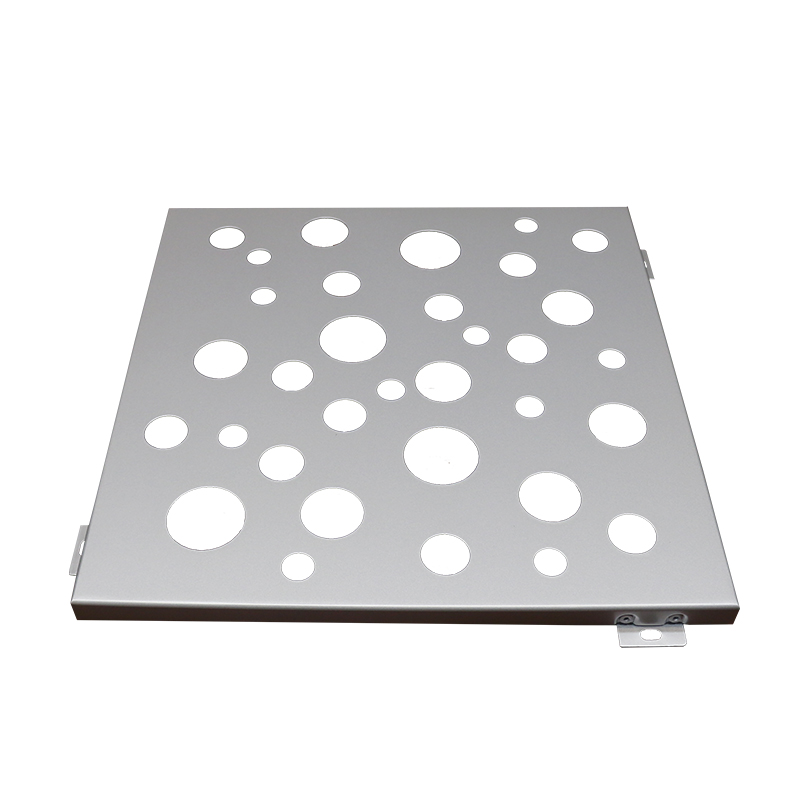

Product Description

Aluminum cladding panel ( sometimes call aluminum veneer, aluminum solid panel ) is used aluminum or aluminum alloy as the raw material, the processing of molding and decorative surface protective coating of architectural aluminum cladding. The use of internationally renowned brands of the United States PPG, Japan’s state legislature fluorocarbon coating company, the Fluorocarbon(PVDF) content of not less than 70%, to ensure that the color and durability of excellent quality. Our production of fluorocarbon liquid sprayed aluminum sheet by the state building materials quality supervision and inspection center testing, product performance in full compliance with “building decorative aluminum sheet”, the national standards.

Product Features:

- Compared with stone and glass, the aluminum solid panels are lighter;

- Different from the fragility of the glass and stone, the aluminum panels have more excellent strength and toughness;

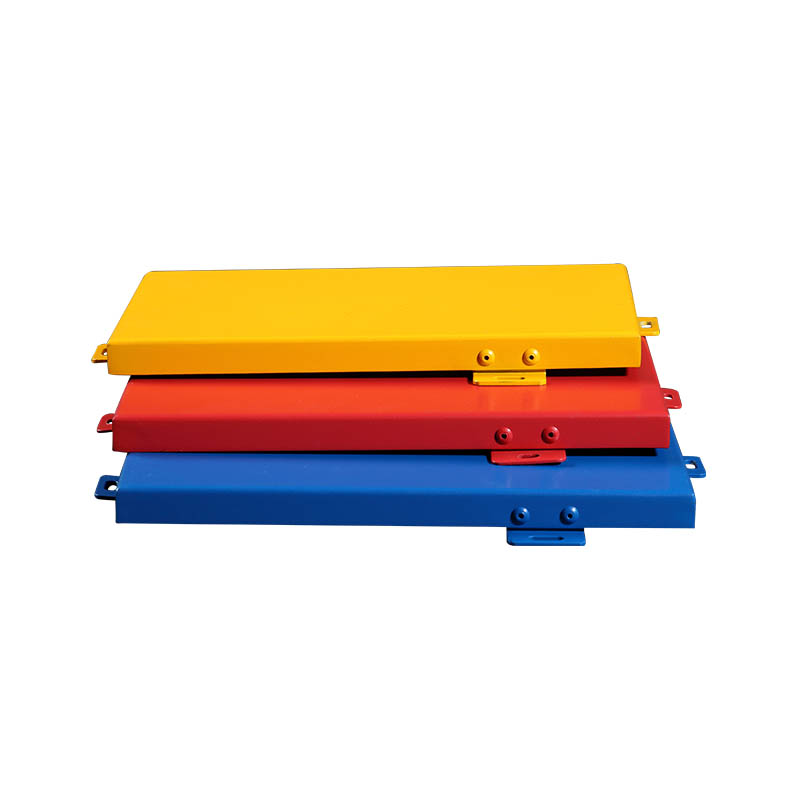

- The aluminum panels are painted with bright colors and beautiful patterns;

- The aluminum panels have the excellent thermal conductivity, conductive, anti-bacterial, fire and cleaning performance, etc.;

- As manufactured by modular production in the factory, the aluminum panels can be installed easier;

- With the fluorocarbon(PVDF) coating, the aluminum panels’ surface will not fade during 15~20 years after installation;

- The aluminum panels are environmental friendly and 100% recyclable compared with the glass and stone curtain wall.

Product Specification:

| Item Name | Aluminum Cladding Panel, Aluminum Veneer |

| Materials | A1100 H24, A3003 H24, A5052 H24, A5005 H24 or according to customers requirement |

| Thickness | 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm, 3.5 mm, 4.0 mm, 5.0 mm |

| Fabricating Process | cutting, bending, jointing, welding, polishing |

| Color | RAL color or Customized |

| Surface |

|

| Max Size | 1600 mm * 1300 mm * 2400 mm ( L * W * H ) |

| Certification | CE, ISO 9001, ISO 14001, SGS |

| Coating Color Guarantee |

|

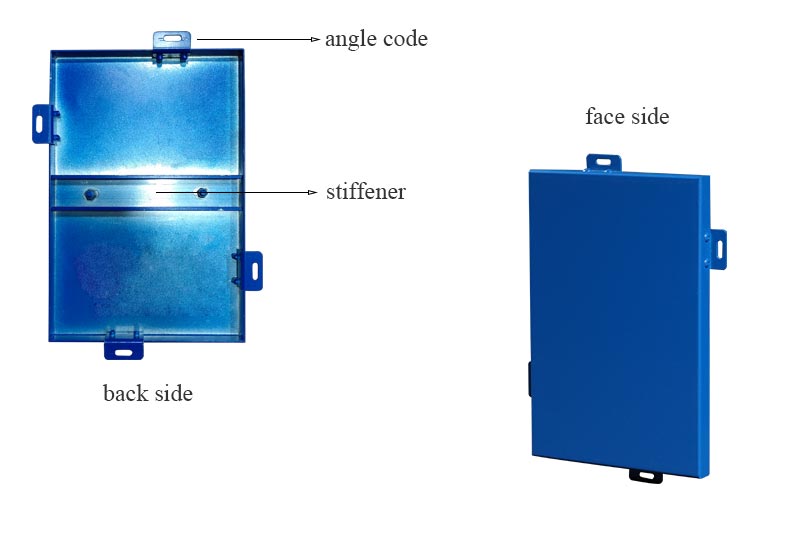

Product structure

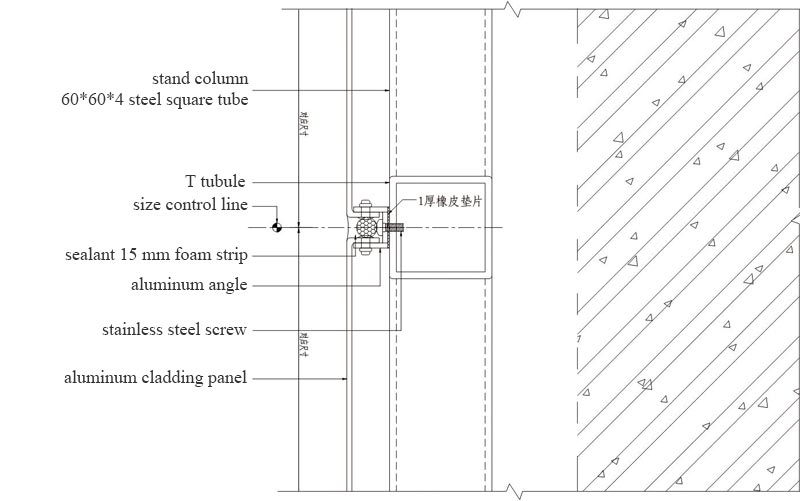

Installation Structure

Project Case