Product Description

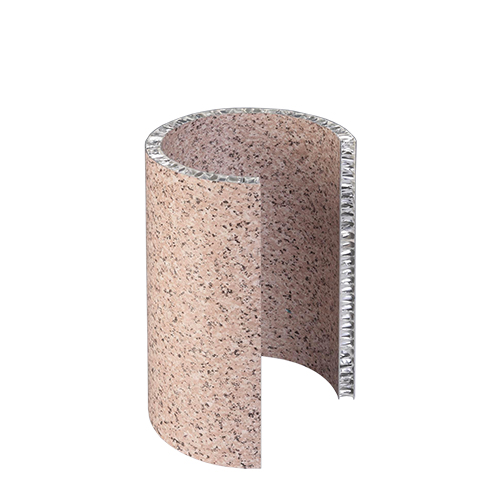

Aluminum honeycomb core is strongly laminated with multi-layers of aluminum foils by adhesive film, which are expanded into various sizes per customers’ request. Its performance mainly depends on aluminum foils ( aluminum alloy grade 3003/ 5052 ), node adhesive and specification ( foil thickness & cell size ).

Aluminum honeycomb is highly desirable due to its incredibly high strength-to-weight ratio and is applicable wherever lightness and strength are required, such as office building, commercial center, aerospace, marine, defence, rail and automotive industries, etc. And is a new material of energy conservation, environmental protection and health.

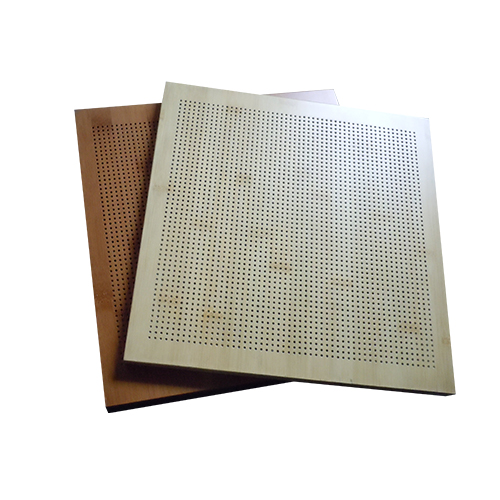

Advantages of aluminum honeycomb panel

- Energy saving, green material: good thermal and sound insulation & sound insulation, fire resistance;

- High windload resistance: high strength & rigidness and stable structure of honeycomb core;

- Easy installation & low labor cost: light weight;

- Good decoration: excellent flatness & wide color selection.

Product Specification

| Specification | overall thickness: 10 ~ 100 mm |

| width ≤ 2200 mm | |

| length ≤ 6000 mm | |

| Face Sheet | Materials: high grade aluminum alloy ( 3003, 5005, 5754, AA 1100 ) |

| Thickness ≥ 1.0 mm ( curtain wall standard ) or ≥ 0.7 mm ( non-standard ) | |

| Core | Materials: high grade anti-corrosive aluminum honeycomb core |

| Aluminum foils’ thickness: 6 mm | |

| Bottom Sheet | Material: high grade aluminum alloy ( 3003, 5005, 5754 ) |

| thickness ≥ 0.7 mm ( standard ) or ≥ 0.5 mm ( non-standard ) | |

| Binder | Two-component high-temperature curing polyurethane adhesive of fuller/ hot melt adhesive membrane. |

| Treatment | PVDF coating, roller coating, powder coating, anodized, wood grain |

| Color | RAL color or customized |

| Density | 5.0 ~ 7.5 KG/ m2 |

| Certificated | CE, SGS, ISO 9001:2000 |

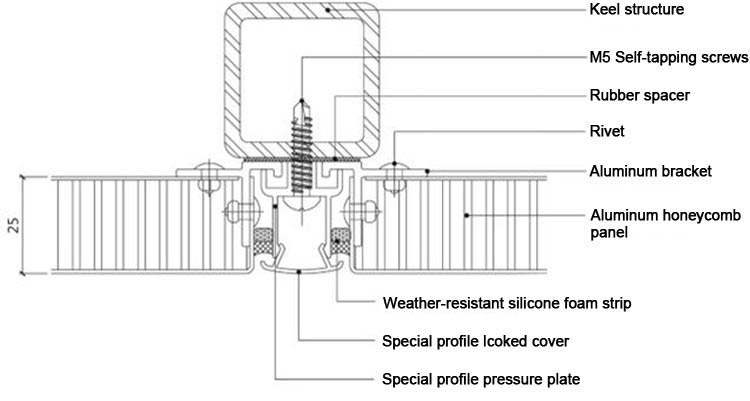

Product Installation Structure

Aluminum Honeycomb Applications: