Product Description

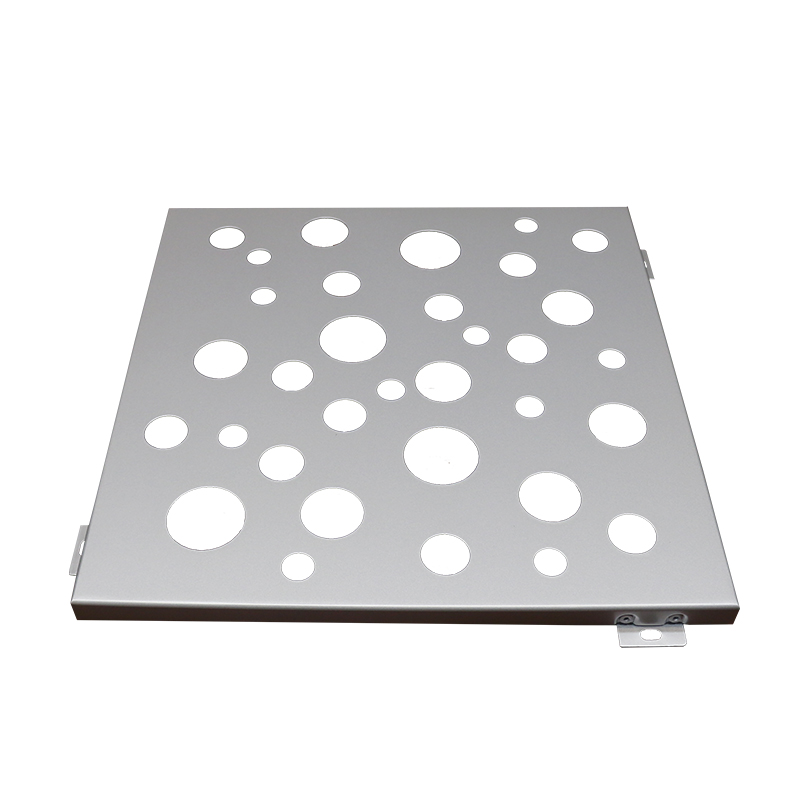

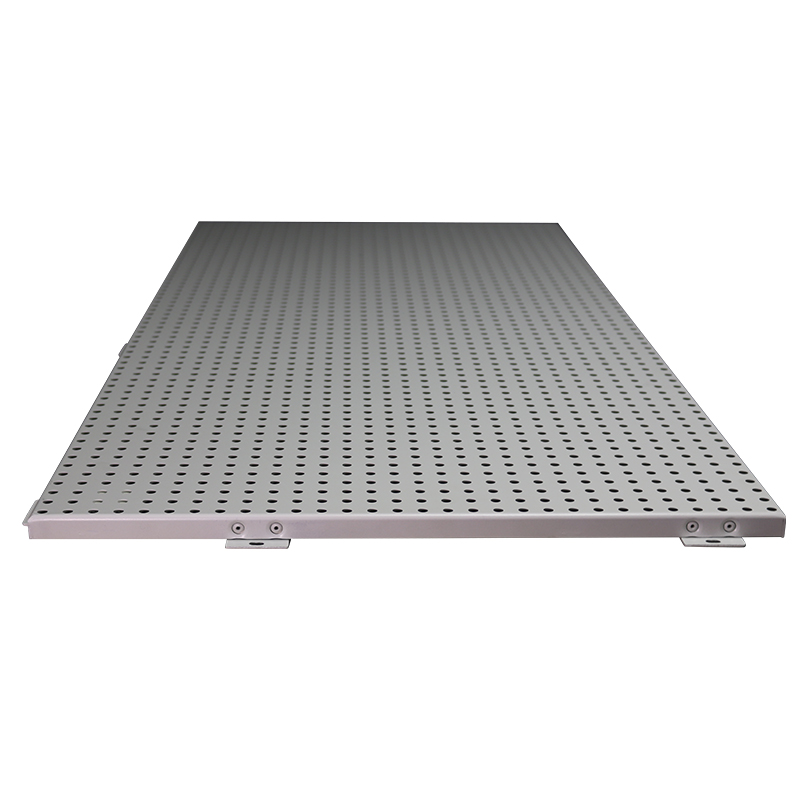

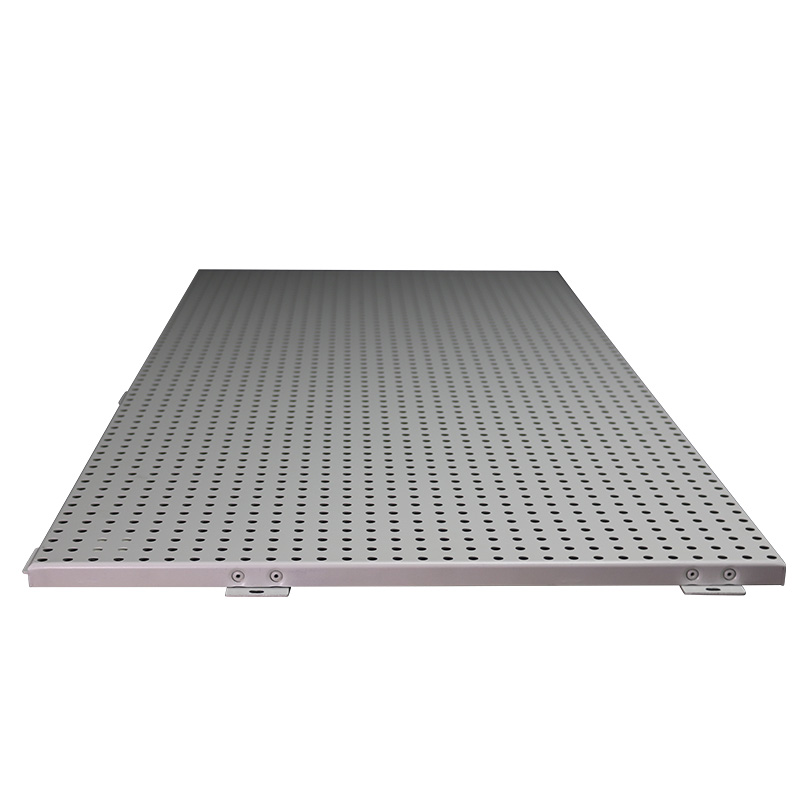

Aluminum Perforated Panels adopts the imported automatic CNC punching machine from Germany, which can easily realize the processing of various complex hole shapes of punched aluminum veneers, and meet the needs of customers for various hole shapes, irregular apertures and tapered holes of punched aluminum veneers. It guarantees the precision of punching processing, meets the high standards of architectural design to the greatest extent, and fully expresses the innovative ideas of architectural design.

At the same time, the high-speed work of the advanced processing equipment for punching aluminum veneers can guarantee the production cycle of punched aluminum veneers and ensure the progress of the project.

Aluminum Perforated Panels are used in the decoration of high-rise buildings such as lobby facades, pillars, pedestrian bridges, elevator edging, and indoor shaped ceilings.

Product Features:

- Compared with stone and glass, the aluminum panels are lighter;

- Different from the fragility of the glass and stone, the aluminum panels have more excellent strength and toughness;

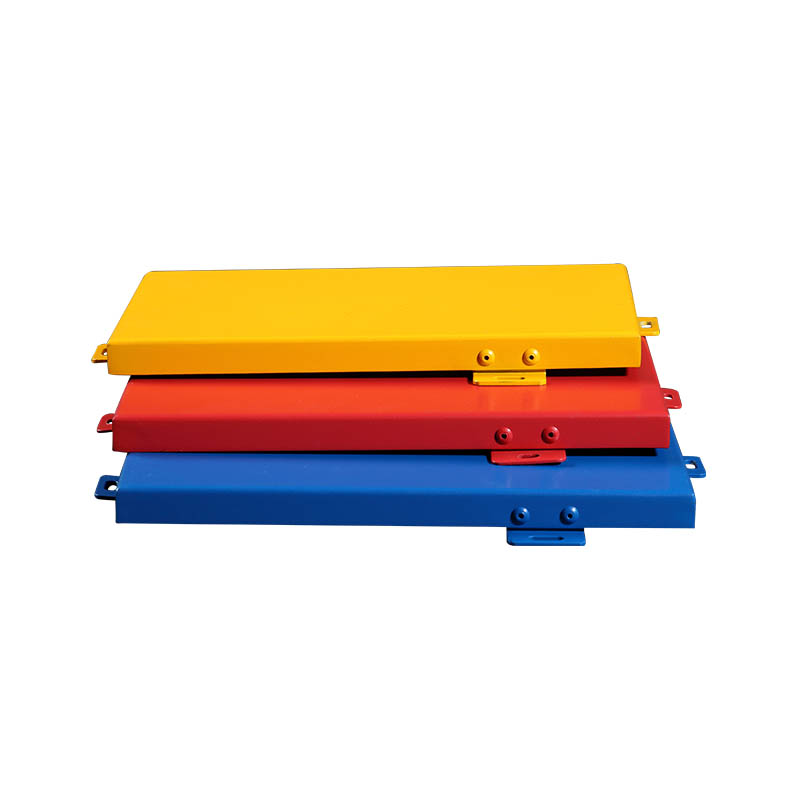

- The aluminum panels are painted with bright colors and beautiful patterns;

- The aluminum panels have the excellent thermal conductivity, conductive, anti-bacterial, fire and cleaning performance, etc.;

- As manufactured by modular production in the factory, the aluminum panels can be installed easier;

- With the fluorocarbon(PVDF) coating, the aluminum panels’ surface will not fade during 15~20 years after installation;

- The aluminum panels are environmental friendly and 100% recyclable compared with the glass and stone curtain wall.

Product Specification:

| Item Name | Aluminum Perforated Panels |

| Materials | A1100 H24, A3003 H24, A5052 H24, A5005 H24 or according to customers requirement |

| Thickness | 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm, 3.5 mm, 4.0 mm, 5.0 mm |

| Fabricating Process | cutting, bending, jointing, welding, polishing |

| Color | RAL color or Customized |

| Surface |

|

| Max Size | 1600 mm * 1300 mm * 2400 mm ( L * W * H ) |

| Certification | CE, ISO 9001, ISO 14001, SGS |

| Coating Color Guarantee |

|

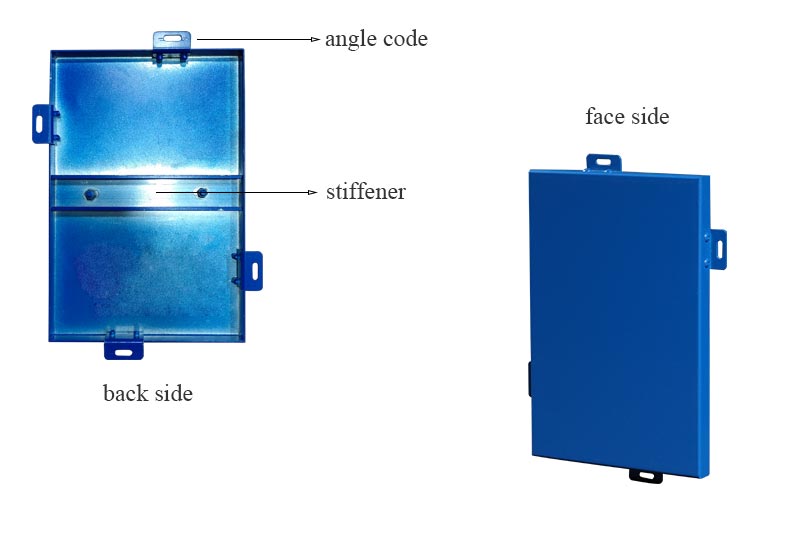

Product structure

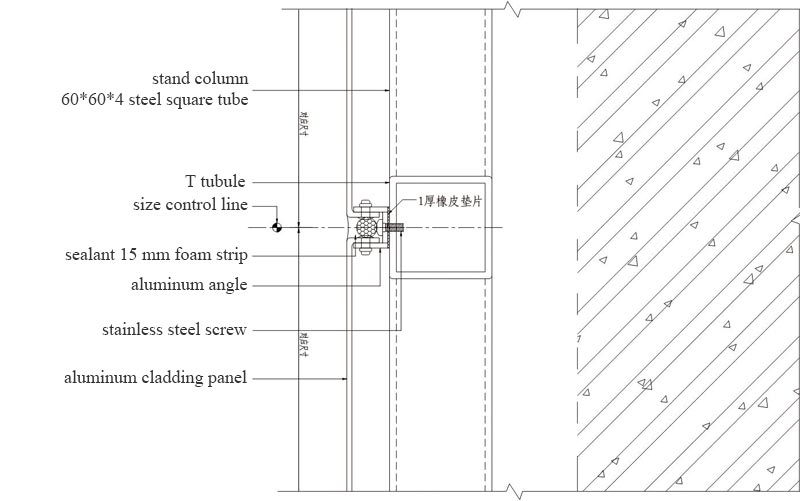

Installation Structure

Project Case