Product Description

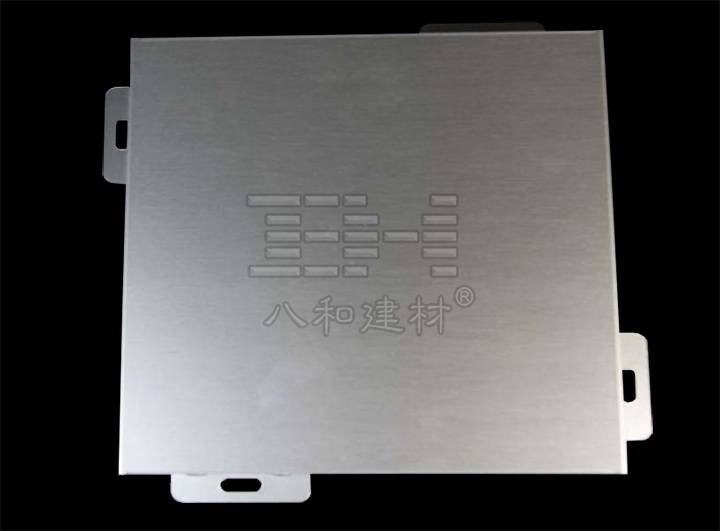

The surface treatment technology of anodized aluminum veneers is different from ordinary painting technology. It electrolyzes the conductive acidic electrolyte through electric current to oxidize the aluminum metal surface constituting the anode, and naturally grows a thick and fine oxidation on the aluminum surface. Aluminum protective film, this oxide film is not an additional layer and will not fall off.

Product Features:

- The anodized aluminum veneer has strong metal feeling: the aluminum veneer treated by the anode has high hardness, high gem grade, good scratch resistance, no paint cover on the surface, retaining the metallic color of the aluminum plate, outstanding modern metal sense, and improving the product level and added value.

- The anodized aluminum veneer has strong stain resistance: easy to clean, simple to protect, no fingerprints, simple cleaning, no corrosion mottle.

Product Specification:

| Item Name | Anodic oxidation Aluminum Panel |

| Materials | A1100 H24, A3003 H24, A5052 H24, A5005 H24 or according to customers requirement |

| Thickness | 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm, 3.5 mm, 4.0 mm, 5.0 mm |

| Fabricating Process | cutting, bending, jointing, welding, polishing |

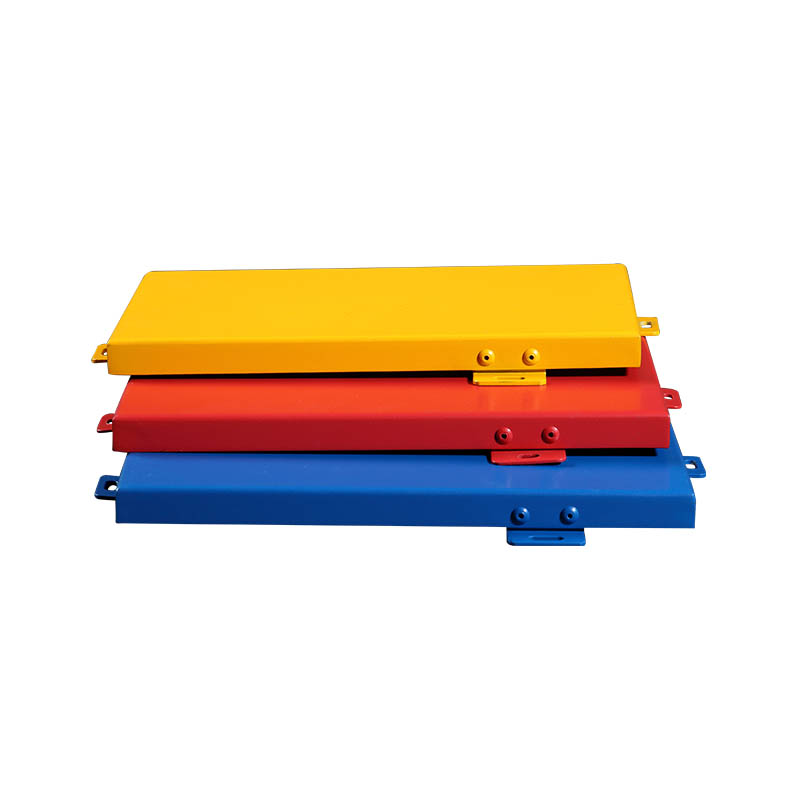

| Color | RAL color or Customized |

| Surface | Anodic oxidation treatment |

| Max Size | 1600 mm * 1300 mm * 2400 mm ( L * W * H ) |

| Certification | CE, ISO 9001, ISO 14001, SGS |

| Color | Anodized, metal color or customized |

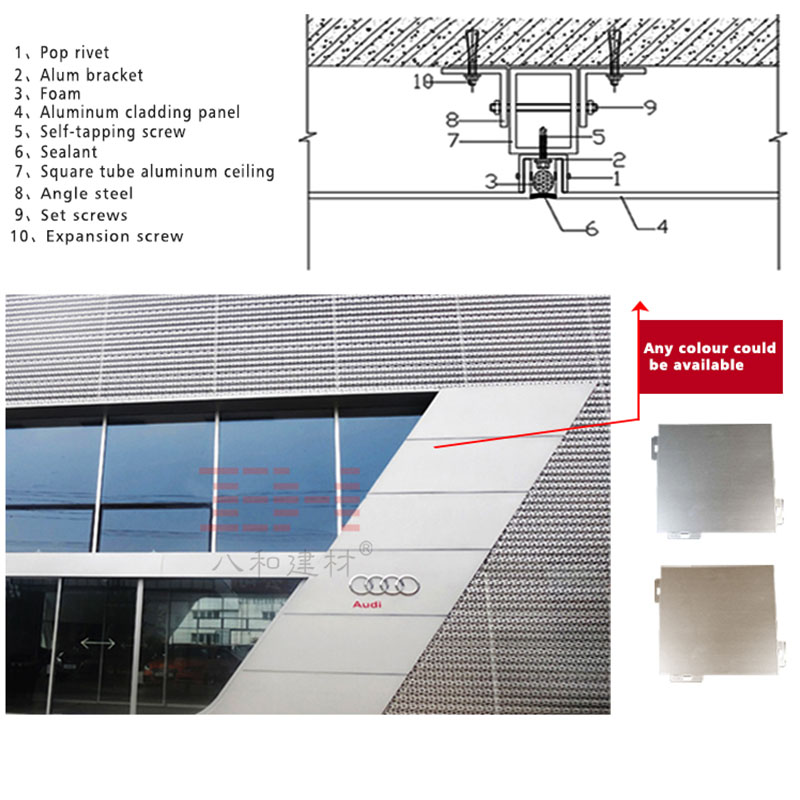

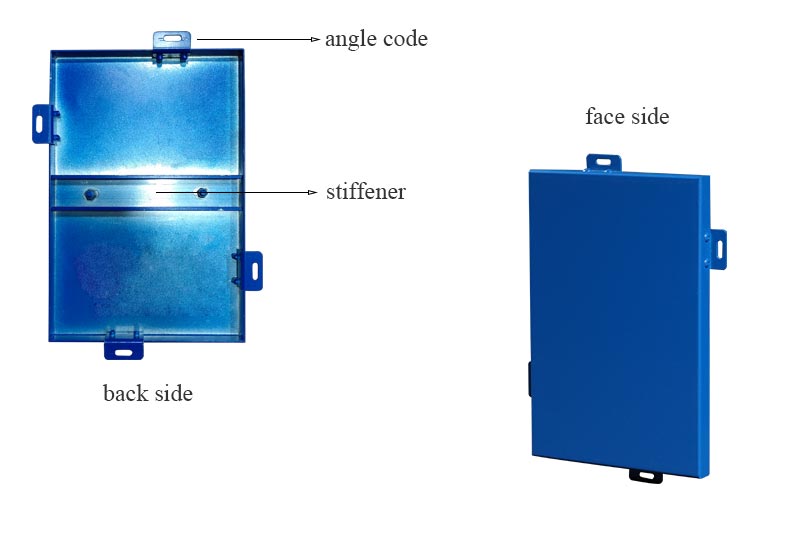

Product structure

Installation Structure

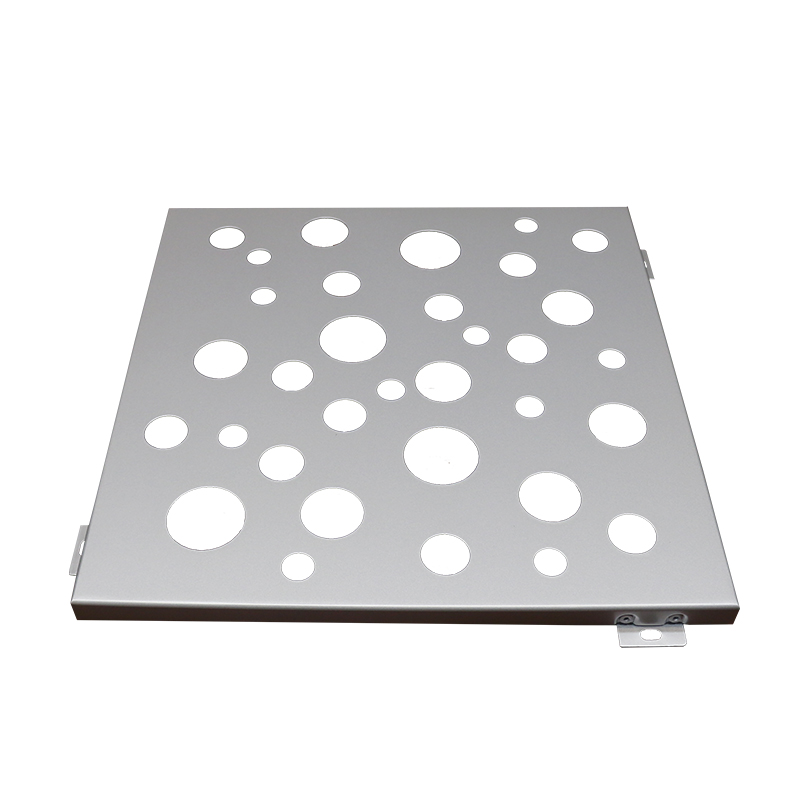

Project Case