Product Description

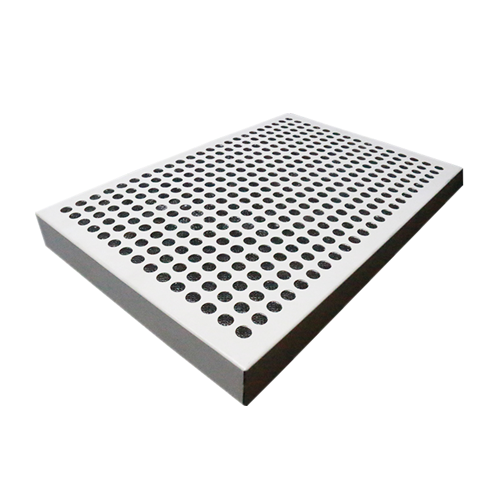

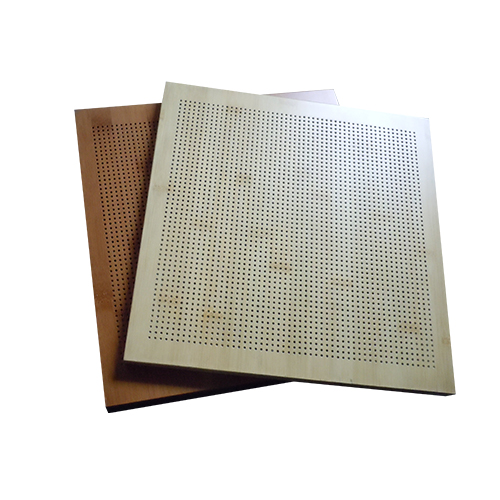

Perforated aluminum honeycomb panel is processed into a hole as required, and a layer of sound absorbing material is added under the panel, and then processed by a composite technique.

The honeycomb core material of the punched aluminum honeycomb panel has a volume of only 1% to 3%, and the rest of the space is air sealed in the aluminum plate and the honeycomb structure. The sound insulation and heat insulation performance of the air is superior to any solid material, heat and sound waves. The transmission is greatly limited, so the aluminum honeycomb panel has good sound insulation and heat insulation properties.

Advantages of aluminum bamboo honeycomb panel

- Energy saving, green material: good thermal and sound insulation & sound insulation, fire resistance;

- High windload resistance: high strength & rigidness and stable structure of honeycomb core;

- Easy installation & low labor cost: light weight;

- Good decoration: excellent flatness & wide color selection.

Product Specification

| Specification | overall thickness: 10 ~ 100 mm |

| width ≤ 2200 mm | |

| length ≤ 6000 mm | |

| Face Sheet | Materials: high grade aluminum alloy (1100、3003、5257、6061 ) |

| Thickness ≥ 1.0 mm ( curtain wall standard ) or ≥ 0.7 mm ( non-standard ) | |

| Core | Materials: high grade anti-corrosive aluminum honeycomb core |

| Aluminum foils’ thickness: 6 mm | |

| Bottom Sheet | Material: high grade aluminum alloy ( 1100、3003、5257、6061 ) |

| thickness ≥ 0.7 mm ( standard ) or ≥ 0.5 mm ( non-standard ) | |

| Binder | Two-component high-temperature curing polyurethane adhesive of fuller/ hot melt adhesive membrane. |

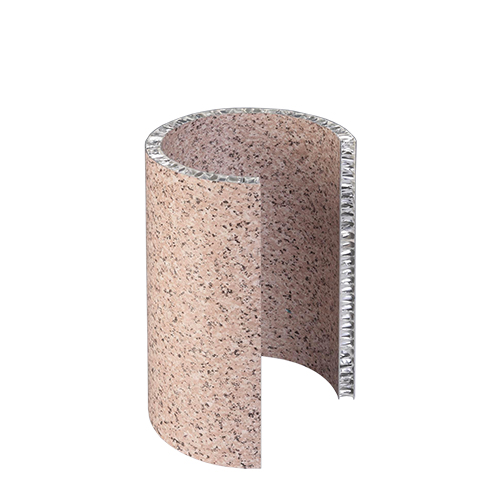

| Treatment | PVDF coated, polyester powder coated, hermal transfer printing, marble effect treatment |

| Color | RAL color or customized |

| Density | 5.0 ~ 7.5 KG/ m2 |

| Certificated | CE, SGS, ISO 9001:2000 |

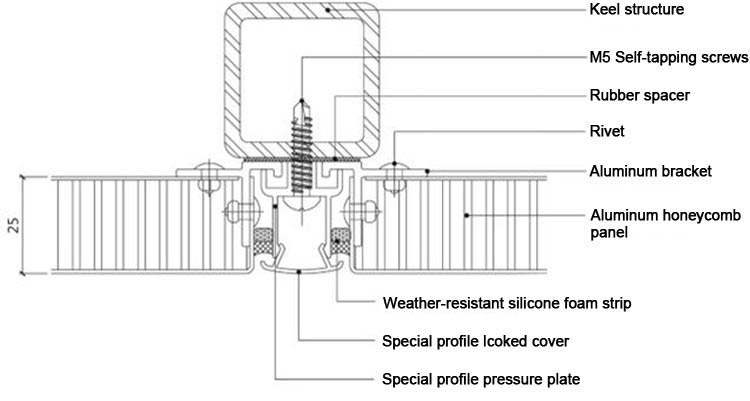

Product Installation Structure

Perforated aluminum honeycomb panel Applications: